Gyratory Crusher

Designed for large-scale mining and aggregate applications with high-capacity continuous operation.

High reduction ratio, stable performance, and robust structure for primary crushing

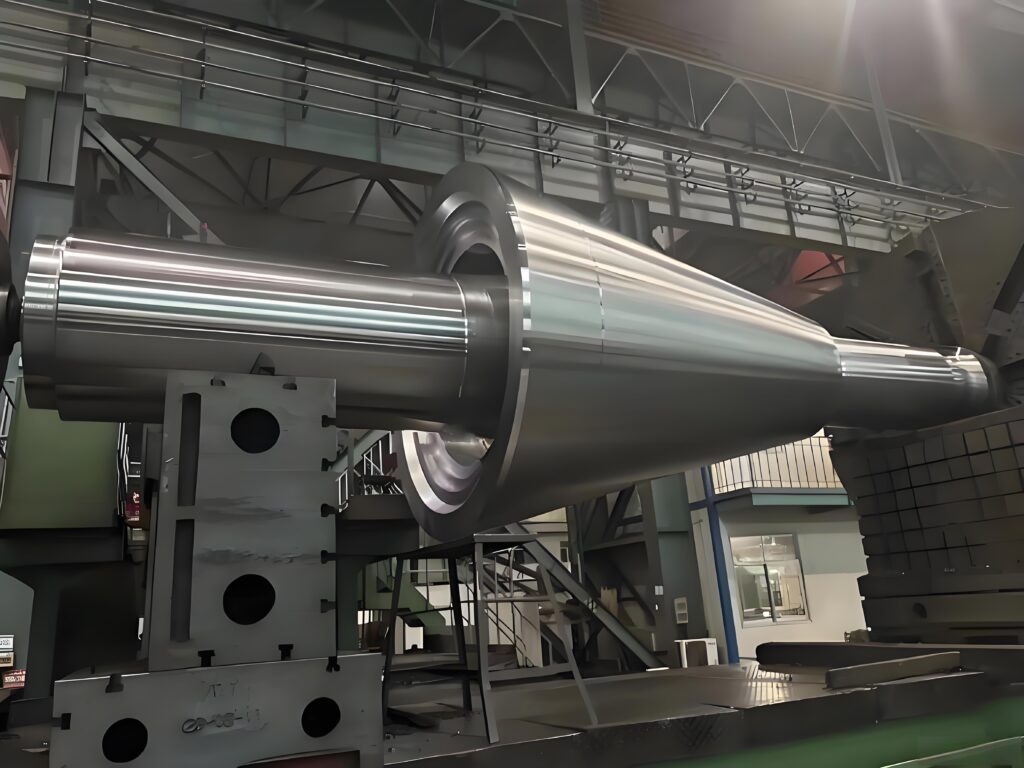

On-site Production of Gyratory Crusher

High-precision heavy-duty shaft manufactured for large industrial equipment.

Machined from high-strength alloy steel, with strict control of concentricity, straightness, and surface finish.

Heavy-Duty Gyratory Crusher Main Shaft

Gyratory Crusher Wear Parts

Made from high manganese steel or high chromium cast iron, requiring excellent wear resistance, impact strength, and crack resistance.

Heavy-Duty Gyratory Crusher Main Shaft

Gyratory Crusher Wear Parts

Material Importance & Production Reliability

The material quality of wear parts is critical to the service life, operational stability, and production reliability of crushing equipment.

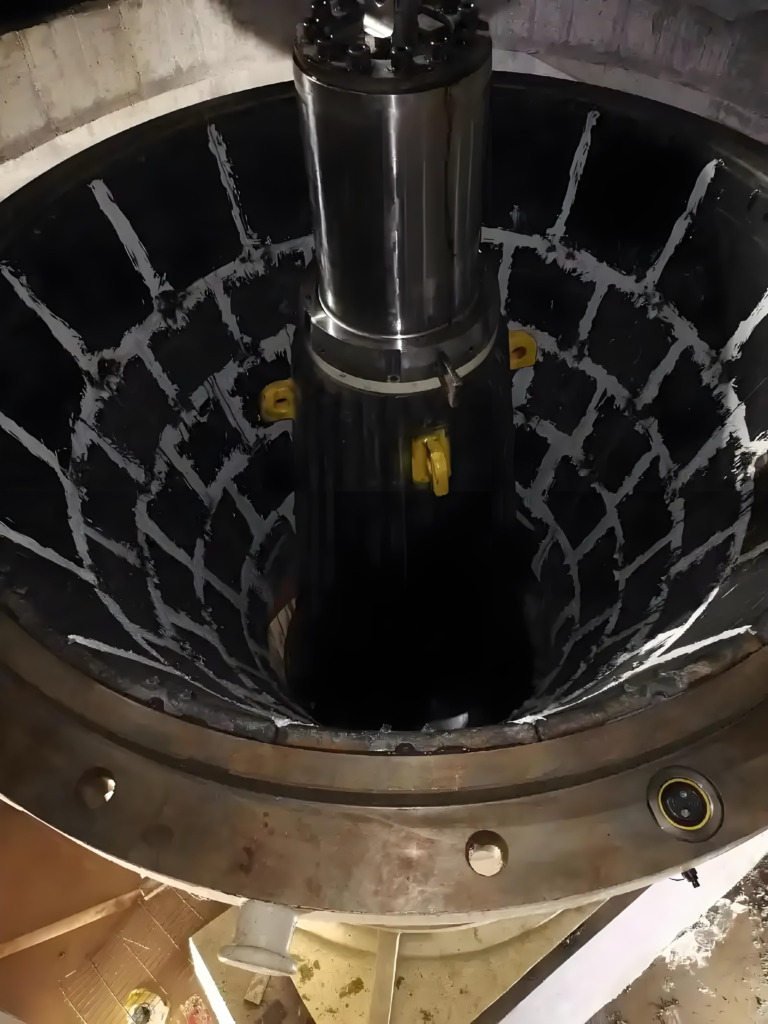

On-site installation of heavy-duty mining components.

Gyratory Crusher Bronze Bushing

The Importance of On-Site Installation and Commissioning for Gyratory Crushers

Proper on-site installation and commissioning are critical to the performance and service life of a gyratory crusher.

On-site installation of heavy-duty mining components.