High-Alloy Hardfacing CO₂ Welding Wire Overview

In CO₂ gas-shielded welding (CO₂ / MAG), various high-strength welding wires are available and are widely used in engineering machinery and mining equipment.

• High-strength structural welding wire: ≥550–690 MPa, suitable for heavy-duty structural applications.

• Low-alloy high-strength welding wire: Balances high strength with good toughness.

• High-strength + wear-resistant welding wire: Designed for areas subject to abrasion while still requiring toughness.

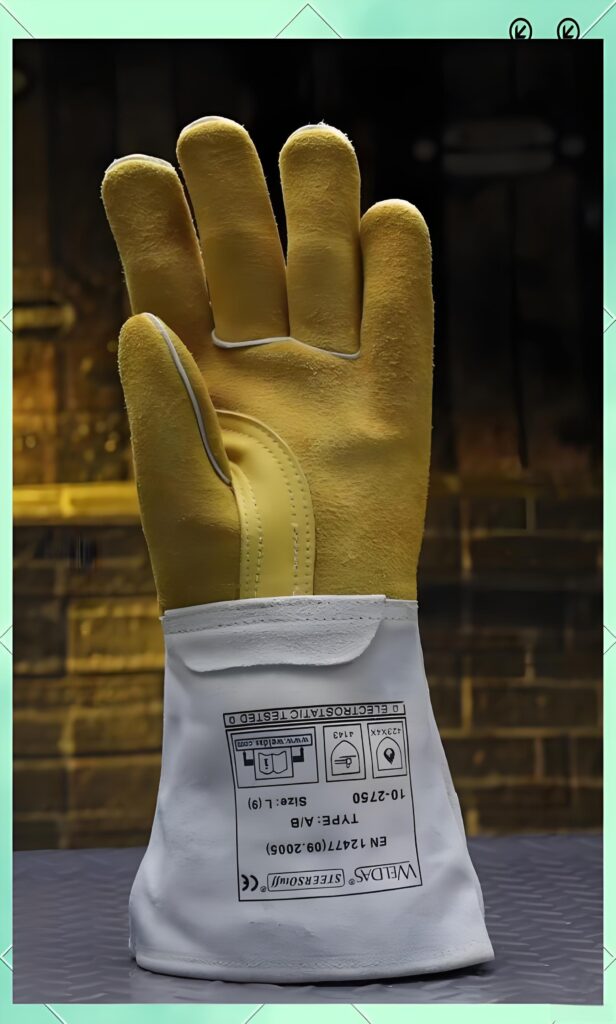

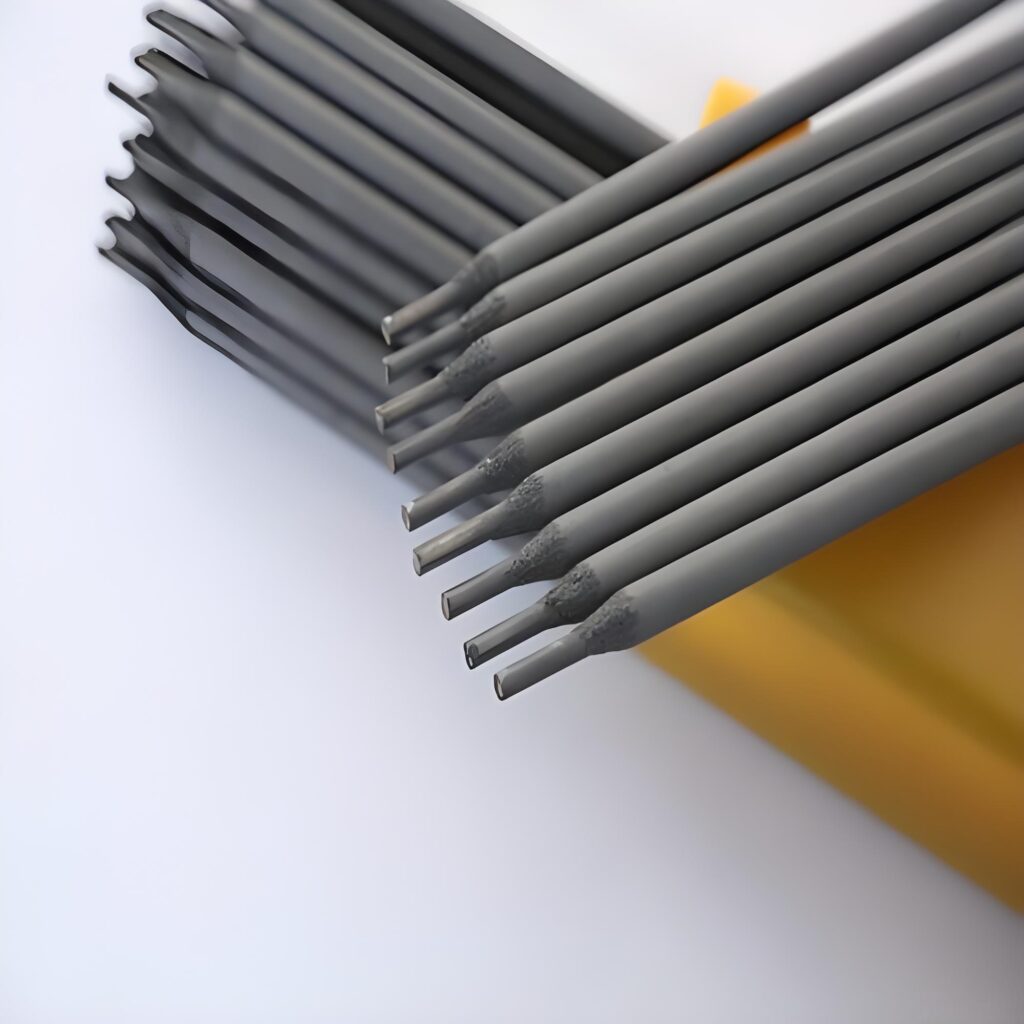

High-alloy hardfacing welding electrode

High-alloy hardfacing welding wire

For equipment such as excavators and buckets that are subject to frequent abrasion from aggregates, high-alloy wear-resistant welding electrodes and wires are required to significantly enhance wear resistance and service life.